“You get what you pay for” goes the old adage, and there is truth in this when it comes to buying t-shirts. Whether you like your t-shirts plain, printed, distressed, mercerised, oversized or fitted, I think you’ll learn something new in this comprehensive guide to buying great quality tees.

T-SHIRT PRICING FACTORS

Fabric

There are many factors at play when a t-shirt is priced. If we disregard designer branding for a moment, one of the most important factors is the fabric from which it is made. This is usually one of cotton, polycotton (polyester/cotton mixes), triblend, modal and bamboo, but there are variations even within these categories that determine the shirt’s eventual cost.

The price of a cotton product is, for example, dependent on whether the cotton itself is of a higher or lower grade (which is determined by the length of each individual baby fibre in the fabric, with longer fibres creating higher quality yarn), whether it is ringspun or not, or if the cotton has undergone special processes like combing, which leads to a smoother finish, but with a greater cost. At ALLRIOT we use combed ringspun cotton – the best quality cotton we could find.

Country of origin

Place of manufacture, too, can affect pricing, with mass-produced t-shirts made in Bangladesh or India being cheaper to make than if the same product was produced in the United States or Portugal. This is simply due to the lower labor costs often found in Asia; even with import duties and shipping costs, t-shirts made in the developing world will still have lower prices than domestically-produced garments.

Naturally, clothes made in Bangladesh bring to mind the appalling conditions and minimal wages of the sweatshops in which they were likely made, and so there is an ethical aspect in buying clothes with a higher price. In addition, cheap t-shirts are often made of inferior materials that are not as environmentally-friendly as their more expensive counterparts.

Distribution model

The distribution model used to sell t-shirts can have a significant impact on their price. Let’s look at the most common distribution models.

Direct-to-consumer

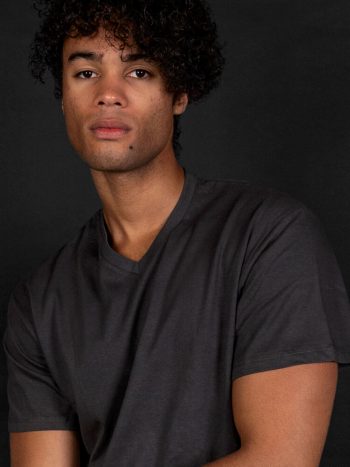

In recent years, the direct-to-consumer (DTC) model has become increasingly popular. Most indie online stores use the DTC model, including ALLRIOT.

The DTC/D2C model involves brands selling their products directly to consumers, cutting out the middleman of retailers. This model can lead to lower prices for consumers as it eliminates the retailer’s markup, which in most cases adds upwards of 50% markup to the cost of a product. Additionally, the DTC model can also result in faster delivery times.

Overall, the DTC model is often seen as the cheapest option for consumers and the most straightforward option for independent t-shirt brands, as it eliminates the retailer’s markup and can result in faster delivery times and more personalised customer experiences.

Wholesale/Retail

Traditionally, t-shirts and other clothing items have been sold through a wholesale model, where manufacturers sell their products to retailers who then sell them to consumers.

Dropshipping

Some online multi-product boutiques use the dropshipping model. Dropshipping involves an online retailer offering products for sale on their website without actually holding any inventory themselves. Instead, they work with a brand who holds the inventory and ships the product directly to the customer once an order is placed.

This model can allow multi-product boutiques to offer a wider range of products without having to invest in inventory. While it’s a great business model for multi-product boutiques, it can result in higher prices for consumers because dropshippers typically add 30% markup. The markup is either swallowed up by the brand or manufacturer (i.e. they sell their products dropshippers at a discount), or passed on to consumers.

When you are buying products from a multi-product boutique, it’s always a good idea to google the brand and compare the prices. If you like a brand and want to help it grow, it’s best to buy directly from them.

Perceived value and branding

The perceived value and branding of a t-shirt can influence how much a customer is willing to pay for it. For example, a hyped up t-shirt with a well-known and respected brand name will likely have a higher perceived value than a generic t-shirt with no recognisable branding. This perceived value may be based on the customer’s belief that the brand represents quality, style, and status, although in reality this isn’t always the case.

In addition, branding can also influence the perceived value of a t-shirt through its design and marketing. A t-shirt with a unique and eye-catching design that appeals to the customer’s personal style may be seen as more valuable and desirable than a plain t-shirt. A well-executed marketing campaign can also create a sense of exclusivity or hype around a particular t-shirt, increasing its perceived value and driving up its price.

EXPERT TIP:

T-SHIRT FABRICS

Cotton

An exceptionally comfortable material, cotton is suitable for all types of clothing, but its softness make it ideal for underwear and T-shirts.

Comfort, however, is not the only reason why cotton is one of the best fabric choices: the material is highly durable and is less likely to rip or tear compared to other fabrics. Its strength also lends itself to absorbing moisture, with cotton becoming 30% stronger when wet, as well as being able to retain a dry feel even after absorbing 20% of its weight in water. In addition, cotton will only start to drip when more than 65% of the garment is wet. Cotton’s unique relationship with water makes it a good choice for making comfortable weather-resistant clothing, and also allows it to effectively withstand long-term washing. Simply put, cotton t-shirts last a long time!

Cotton keeps you cool

Perhaps most importantly from the point of the consumer is the fact that cotton is a natural insulator – it is able to keep a wearer cool in the summer and moderately warm in the winter. This is because cotton fabric traps air between the fabric fibers, and the cotton fibers in garments hold the fabric away from the skin. Cotton’s liquid absorbent properties are also as useful with internal, as well as external, moisture: cotton fabric’s breathable nature is due to the removal of moisture away from the body, drying the skin like a towel. This prevents a buildup of moisture between the skin and the clothing.

Cotton is great for sensitive skin

Cotton is also a hypoallergenic material, meaning that it very rarely causes any allergic reactions, even for people with skin allergies. For this reason it is also often used in medical products such as bandages, as well as for clothing made for babies and infants.

Expert tip:

Polycotton

This material is a blend of natural cotton and synthetic polyester, usually with a mix ratio of 65% cotton and 35% polyester, or a 50/50 split between the two. Unlike polyester, polycotton doesn’t stick to the skin the way that synthetic materials like pure polyester can, but it can still make you sweat more. This is because, unlike pure cotton, polyester fibres in polycotton don’t help with breathability. On the plus size, polycotton doesn’t absorb moisture as well as pure cotton, so you’re less likely to look like you have sweaty armpits.

However, while it is cheaper to produce than pure cotton (and, by association, cheaper to buy), it does not have the same look, and like pure polyester it can be associated with lower-quality products. In addition, it can be harmful for the environment if not recycled and disposed of correctly.

EXPERT TIP:

Triblend

As the name suggests, tri-blend is made of three different fabrics, being 50% polyester, 25% cotton, and 25% Reyon. This gives the material a softer touch than poly cotton, and allows the cloth to stretch a little more. It also gives off a slightly different appearance, with colours being more subtle compared with other fabrics – this is more of a ‘vintage look’, and one of the reasons for tri-blend’s recent surge in popularity. However, as with poly cotton, tri-blend is not an environmentally-friendly material: due to the fact that it is composed of some non-biodegradable components, it can be damaging to the environment if not disposed of properly through recycling.

GREENWASHING ALERT!

Tri blend t-shirts using recycled polyester this seem like a commendable and environmentally-conscious idea, until you realise that plastics can only be recycled once. By buying garments made from recycled polyester, you’re just putting harmful plastics back into the environment.

Also, most clothes are not solely made of polyester: they are mixed with other materials, and this makes recycling far more difficult. In addition, research has found that when clothes made of polyester composites are put through a washing machine, they release microplastics; one garment alone can release 700,000 plastic fibres into the environment.

Marl / Melange

This is not a mix of cotton and polyester in the same fashion as poly cotton or tri-blend; typically Marl (or sometimes called Melange) fabrics may only contain 10% of polyester in its composition. Marl & Melange is, in fact, more of a colour effect usually found in knitted fabrics in which two different colours appear blurred.

The most recognisable example is grey marl sweatshirt fabric, which is made by combining two different coloured yarns in the thread which is used to construct the fabric. The subtle blending of two colours leads to an understated, elegant effect – however, prices can be higher for products made this way.

COTTON ORIGIN AS A MARKER OF QUALITY

Most cotton fabrics come from just 6 countries. The world’s largest producers of cotton are India (24%), China (22%), the United States (18%), Pakistan (7%), Brazil (6%), and Uzbekistan (3%), with the remaining 20% coming from such diverse source countries as Turkey, Australia and Turkmenistan.

Pima cotton

Pima cotton commands a higher price. Like Egyptian cotton, Pima cotton has inherently longer fibres (typically 1.4 to 2 inches in length, compared with most cotton fibres’ average length of 1.1 inches) which – again like its Nile River Delta equivalent – lead to a softer but stronger fabric. Pima fibres, while longer than all other cottons, are still slightly shorter than those from Egypt.

Pima originated in Peru, and while it is still grown in its country of origin, it is now also produced in the southwestern region of the United States, and some parts of Australia (its name, meanwhile, comes from the Pima Indians, who worked to raise the cotton in North America).

EXPERT TIP:

Any product with either Egyptian or Pima cotton in its composition will indicate this in its label, although both luxury types of cotton fiber comprise only 10% of the total of cotton products; all other cotton products will simply read ‘100% cotton’.

FABRIC QUALITY MARKERS

Staple length

The length of a cotton fiber is a key factor in determining its quality, since this affects how the product will feel after it is made, as well as its durability – hence why Egyptian and Pima cotton products, with their inherently longer fibers (and resulting softer feel), are considered luxury goods.

Thread width

Thread width is used to describe how fine the thread of the cotton that was used is. Usually, a single-spy cotton threat is made up of 840 cotton thread yards, so if a pound takes approximately 20 spools, the thread will be described as being either 20s cotton or 20/1; if 30 spools comprise one pound, the thread will be dubbed 30s or 30/1, and so on. In essence, the higher the number the finer the thread – and therefore the finer, softer shirt.

Fabric weave

The greater number of cotton threads in a yarn results in a tighter weave, with 18-single, 30-single and 40-single yarns being the most common types. The tighter the weave, the higher the quality, with a 40-single yarn creating a smoother weave for a t-shirt than a yarn made up of fewer cotton threads.

COMMON FABRIC FINISHES

Mercerisation

Think shiny AF. This is a chemical process which makes use of sodium hydroxide to help make cotton fabric and yarn more able to be dyed. This further strengthens the fibre, gives the garment a shinier appearance than other methods, and allows the fabric to retain its dye longer. The method is named for its 19th century inventor, John Mercer.

After yarn has been mercerised, it can also be ‘gassed’ – that is, quickly passed through a hot flame in order to remove any excess thread in order to create a smoother look.

Combing & Carding

Combed cotton is softer than its regular cousin due to the fact that any short, unnecessary extra threads are removed. The combing process – which involves very fine brushes straightening the fibres (and gives combed cotton its name) – also strengthens the cotton, since the straightened fibres join together more tightly. Due to the extra labor needed to make combed cotton (and the superior product it creates), it is more expensive than regular cotton.

Carded cotton, or uncombed cotton, is spun by the carded spinning technique, which means a wrapped fiber runs perpendicular to the bundle of yarn instead of being aligned in the same direction. Although this process results in a coarser, bulkier or more uneven final product, garments made with the carding are cheaper to produce than other methods.

Carded cotton

Combed cotton

Ring spinning

‘Ring spun’ refers to the fact that yarn goes through a spinning process intended to make each fiber straighter and softer; this naturally results in a garment that feels softer than those made with other methods.

Regular cotton

Ringspun cotton

Slub

Although deliberately created with imperfections, lumps, and a generally rough feel, slub cotton has become popular with fashion designers because it does not cling to the body, still feels light to wear, and does not need to be ironed due to its natural texture. Slub cotton is made by irregular patterns of twists that are put into the cotton before it is weaved.

EXPERT TIP:

When buying cotton t-shirts, you can’t go wrong with combed ringspun cotton. Mercerized t-shirts can look very shiny, and carded cotton doesn’t feel as nice as combed cotton.

T-SHIRT WEIGHTS

Of course, the weight of a t-shirt affects how it feels to the wearer – a lightweight shirt will feel airy and move freely, while a heavyweight will be warmer and more durable, although at the expense of the wearer being very conscious of wearing it. Yet weight is also able to affect the price, especially if the shirt is being imported.

OZ and GSM explained

The weight of t-shirts usually ranges between 3 oz at their lightest, to standard weights of 4.5 to 5 oz, to heavier weights of 6 oz or more. Shirts under 3 oz may not be very durable, and so are not as common as those of higher weights.

This does not, of course, mean that the shirts themselves weigh three ounces or six ounces – the weight refers to much a square yard of fabric weighs. Sometimes the weight is listed as ‘GSM’ – grams to square meter. GSM to oz can conversions can be done by dividing the GSM by 33.906.

EXPERT TIP:

Some people prefer lighter weight t-shirts, whereas others prefer heavier weight tees. It’s down to your personal preference. We suggest finding out the GSM or OZ value most commonly used by your favourite brand and using it as a guide.

ALLRIOT unisex tees are 180 GSM in the UK, which is a bit on the heavyweight t-shirt side. Because we use combed ringspun cotton, they have a really nice hand feel and don’t feel to heavy at all.

In the States and Canada, we use a slightly lighter t-shirt which comes to about 4.3 OZ / 150 GSM.

T-SHIRT CONSTRUCTION

Tubular vs Side Seam

There are two general types of t-shirt construction: tubular and side seamed. Taking its name from its shape, the tubular design is cheaper and requires less sewing: a slice is made into the tube to make a circular piece of fabric, after which the arms and neck are sewn on.

Side seamed shirts follow the contours of the body more flatteringly as – like the name suggests – the seam of the shirt follows the side of the torso, but the front, back and sleeves are all also individually cut. This design is generally considered to be a better alternative (and more popular) than its tubular counterparts, although it depends on cotton quality. Have you ever noticed that the seams on some of your t-shirts twist around the body in a really funny way? This is due to either low cotton quality, or pattern pieces cut incorrectly (i.e. off-grain). We use a mix of tubular and side seamed construction in our cotton tees.

COMMON T-SHIRT CONSTRUCTION TERMS

1x1 rib

This type of stitched fabric is commonly used for T-shirt sleeves and neckbands since it is very elastic while retaining its original shape.

Twin needle stitch

This entails parallel stitching that is mainly used for bottom and sleeve hems, which increases the durability of the shirt and creates a more elegant look.

Taped neck and shoulders

This is a fabric sewn to cover the edge of the sewing construction that closes the front and rear of a shirt’s shoulder section, in order to provide better comfort and durability.

Crew neck

This is a type of shirt that has a rounded neckline and no collar.

V-neck

As the name suggests, the neckline is in the shape of a V. Like the crew neck, it does not have a collar.

Raglan sleeves

These sleeves extended in one piece to the collar and do not have a shoulder seam; these sleeves are often said to give off a more casual appearance than their set-in equivalents.

Ringer T-shirt

Scoop neck

This collarless shirt has a neckline significantly lower cut neckline than other types of shirt.

Set-in sleeves

This is when sleeves are connected to the torso of a garment at the shoulder, which then continues along the armhole.

T-SHIRT FIT JARGON

As the names suggest, you can buy oversized (aka baggy or loose fit) t-shirts, regular (aka unisex or standard fit), and slim (aka fitted) t-shirts.

Semi-fitted t-shirts also exist. They are usually a bit more tailored than regular fit tees, but not enough to make a big difference.

Now, let’s look at most commonly used t-shirt fit jargon.

Size tolerance

This is the allowable limit of variation in a shirt measurement. With an accepted tolerance of one inch, there can be a deviation of plus or minus one inch from the size listed on the size chart.

Shrinkage

Shrinkage is one of the few disadvantages cotton has when compared with its synethic-infused counterparts. Since cotton is a natural fiber, it shrinks because of the tension that is applied to its yarn and fabrics during its production. This tension is then released by heat from the washer, dryer, steam, or even sunlight, which causes the fabric to be reduced to its natural size.

This is why most cotton clothing will shrink during its first washing. This can be avoided by hand-washing the clothes, or by using cold water and the most delicate cycle of a washing machine. The drying machine should also not be used; instead, leave cotton clothes to dry on washing lines or racks; if you must use a dryer, set it to the lowest heat setting possible.

It is also worth investigating whether the cotton used in the shirt has been preshrunk: this is, however, often true for most standard, 100% cotton t-shirts.

EXPERT TIP:

Well-fitted, quality t-shirts should not suffer from major shrinkage or substantially change their shape even after many washes: this is the most definite way to tell the difference between a cheaper product and a quality product. Having said that, cotton is a natural fibre and has a mind of its own, so some shrinkage is perfectly normal.

T-SHIRT QUALITY INDICATORS TO WATCH OUT FOR

After parting with hard-earned cash, naturally you’ll want to have made an investment in a shirt that will retain its quality for as long a time as possible. There are a number of factors to consider in determining a shirt’s true quality listed below; unfortunately, not all can be taken into account at first glance.

Durability

Garments made from long fibers are typically of a higher quality due to the fact that they are composed of finer yarn, which creates a stronger fabric (hence the price of Egyptian and Pima cotton).

Sewing defects

There are several things to look out for in a shirt’s sewing. The cloth around the seams of the shirt should be smooth and not ruffled or puckered, nor should edges be frayed, or the colors of the sleeves different from the rest of the shirt. A ‘wave’ of fabric splayed across the upper chest of the shirt and cheap graphics for the design are also indicators of a low quality garment.

Pilling

Pills can be seen on shirts when clusters of short or damaged fibers on the surface of the shirt are forced together, making knots or balls appear in the cloth. These usually appear as a result of normal wear and use.

Colourfastness

Over time, colors should look fresh rather than fade; faded colors after years of use are glaring hints to low quality.

Drape

Natural drapes are essential for the design of elegant clothing; it is a bad sign if a shirt does not have any natural draping when worn.

An obvious point to look for in a shirt, but at least one can ascertain comfort before parting with any money. The cloth must feel comfortable when worn – short fibers in the fabric can create scratchiness or itchiness, since unlike long fibers they are not woven evenly into the cloth.

Pattern matching

This can also be seen at first glance: beware any garment with uneven patterns.

Breathability

Air pockets between individual threads can cause thermal insulation, which reduces the breathability of the cloth and results in sweating. When finely combed cotton is woven tightly, the skin will be able to breathe within the shirt more easily.

Unifirmity

All one should see when closely examining a shirt is a regular pattern of rows; any inconsistencies in the individual threads are an effective warning sign.

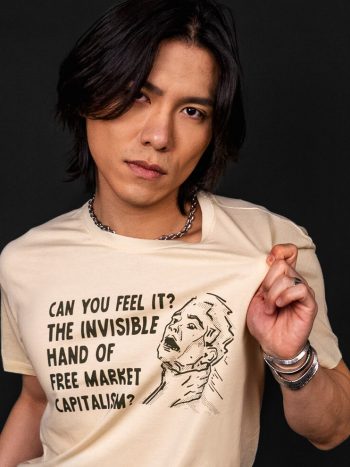

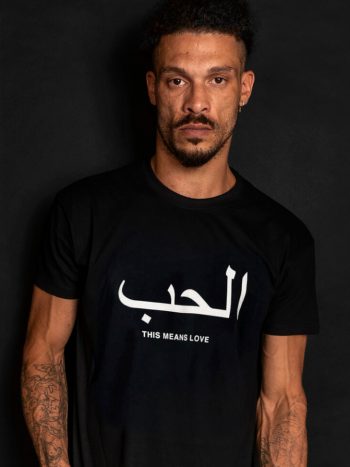

LAST BUT NOT LEAST, T-SHIRT PRINTING METHODS

The process in which designs or graphics are placed onto a graphic t-shirt can drastically affect its look, from both an aesthetic and quality standpoint.

Water-based screen printing

With this method, multiple screens are used in multi-colored designs. This method – one of the oldest but most effective ways of printing on T-shirt – creates long-lasting and high-quality designs.

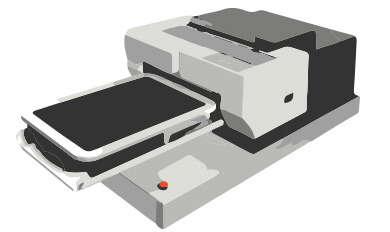

Digital printing

Digital printing involves artwork being processed by a computer, and then printed directly onto the surface of your product.The fact that the digital printer does not use screens allows for a photographic print, with much higher image quality than traditional screen printing. As the ink is applied more thinly, digital printing is best used on lighter coloured shirts to allow the design to stand out. We use digital printing to print our funny political tee shirts.

Curious to learn more about t-shirt printing? Head to our t-shirt printing methods explainer for a more detailed overview.