BRIEF HISTORY OF COTTON FABRIC

A plain cotton t-shirt is a wardrobe staple, but what makes cotton fibre so special? It remains unclear where cotton plants were first grown, with ancient cloth being discovered in areas as geographically diverse as Egypt, Mexico, and the Indian sub-continent. As a resource, it has shaped the course of many nations’ histories, and not just in its use for garments: demand for the crop drove the evils of the slave trade in the early years of the United States, and the eventual Civil War disrupted cotton exports to the outside world, causing an economic crisis in the British Empire and (indirectly) another war in East Africa.

Although the technology used in the textile industry has advanced considerably since the days of the cotton gin, its economic importance has remained unchanged; it is still used throughout the world more than any other fibre, and, on average, generates $120 billion for businesses in the United States alone.

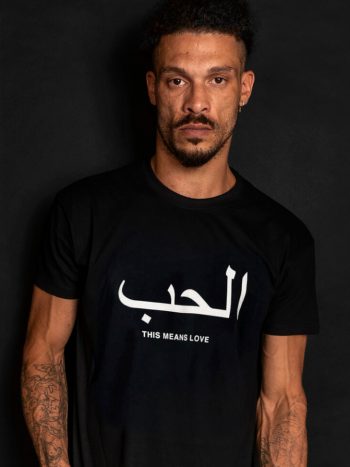

We use only 100% cotton for our unique and original satirical t-shirts.

COTTON HARVESTING

Cotton is grown only once per year, but every part of the cotton plant is useful: even the short fuzz on the seed, the linters, which are still attached to the seed after cotton has been ginned (the ginning process separates the leaves and seeds from the cotton fibers), are a source of cellulose for making plastic-based materials, as well as for the padding that goes into mattresses, chairs, and car seats.

COTTON PROCESSING

After the cottonseed has been crushed, its three components –oil, meal and hulls – are used for other purposes. Cottonseed oil is mostly used for cooking oil and salad dressing, while the meal and hulls that remain are used as feed for livestock, poultry and fish, or as fertilizer. The stalks and leaves of the cotton plant are plowed under to enrich the soil. In addition, cottonseed can also be used in making a protein-rich concentrate to be put into baked goods and other food products.

The most prominent part of the plant, however, is the fibre, or lint, which is used in the making of cotton cloth. Cotton is first made into yarn by being processed through a textile mill’s carding machine, which rearranges the fibres into a type of web. The web is then rearranged into a single strand of fibre which is then joined with other strands to give it durability and strength; the lint has now become yarn.

WEAVING COTTON YARN

The yarn can then be either knitted or woven into shape.Weaving results in a cloth that can often only be stretched in only one direction, giving less elasticity compared to fabrics made from knitting; knitted threads, meanwhile, are thicker than their woven counterparts, making bulkier-looking fabrics compared to woven cloth, which appears to be lighter. After the weaving or knitting process is complete, the material is smoothed over so that it can receive any dye or chemical treatment that will be added afterwards.

WHAT DOES 'RINGSPUN COTTON' MEAN?

The cotton we use in our awesome t-shirts is ringspun, but what exactly does it mean?

REGULAR COTTON

Regular cotton is a mixture of short, thick, low quality fibres. It is cheaper to produce and typically yields a lower quality yarn. Printing on regular (carded) cotton results in a grainy low definition print.

RINGSPUN COTTON

The finer fibres are tightly twisted together, which results in a stronger, leaner, cable-like yarn. Ringspun yarns yield a smoother, more durable and lustrous fabric that’s a pleasure to print on. Result: perfect t-shirt!

Interested in learning more about cotton t-shirts? Head to the ultimate t-shirt buying guide. See you there.