The process in which designs or graphics are placed onto a graphic t-shirt can drastically affect its look, from both an aesthetic and quality standpoint. The methods listed below indicate which processes are better for which types of design and graphics.

WATER-BASED SCREEN PRINTING

With this method, quality results come from use of a nylon mesh and a stencil or template. The nylon mesh holds the stencil in position, and a water-proof material blocks the negative space on which the design will be placed. Ink is then spread all over the screen, after which the screen is removed and the design is left to dry and cure.

As a screen only supports one colour, multiple screens are used in multi-coloured designs. This method – one of the oldest but most effective ways of printing on t-shirt – creates long-lasting and high-quality designs. The durability of screen printed products slightly negates the fact that inks used in screen printing can be harmful to the environment.

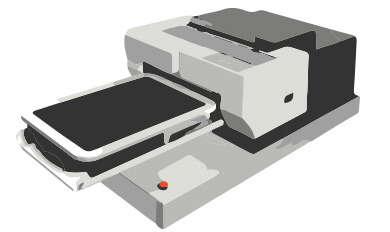

DIGITAL PRINTING (DTG)

Digital printing involves artwork being processed by a computer, and then printed directly onto the surface of your product. Digital printing is not a heat transfer since the ink is directly printed into the fabric of the shirt. The method is best used for items that require significant detail. The fact that the digital printer does not use screens allows for a photographic print, with much higher image quality than traditional screen printing. As the ink is applied more thinly, digital printing is best used on lighter colored shirts to allow the design to stand out. Ink used in this process is less thick than in screen printing, making the method more environmentally-friendly.

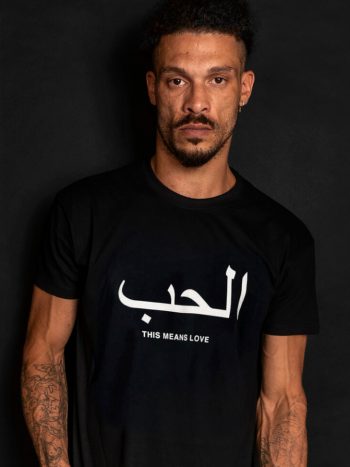

DISCHARGE PRINTING

Discharge printing is the process of using water-based inks to bleach the manufacturer’s dye out of a shirt and replacing it with another chosen color. This is achieved by using water-based inks that soak into the fabric instead of just sitting on top of it. Typically this is done with cotton shirts that are black, gray or darker in color. Use of this method results in a softer look and feel compared to plastisol ink, and also retain the detail of a design.

The shirt will also have a more ‘vintage’ appearance. If eco-friendly inks are used, this method is also environmentally-friendly.

It’s important to note that some coloured cotton t-shirts, in particular orange and bright blue colourways, might need to be printed with plastisol inks instead of water-based inks because otherwise t-shirt colour bleeds into the design.

OTHER T-SHIRT PRINTING METHODS

DYE SUBLIMATION

Sublimation printing is where the printer cleverly uses the sublimation process to dye a substrate (polyester fabrics or other items with a polymer coating or surface) by turning dyes from a solid into a gas and back into a solid again, while bonding with the polymer materials present in the substrate or product. Dye sublimation works by penetrating the surface of the substrate with ink.

It creates attractive and permanent colours that are embedded in the fabric rather than printed on the surface; images on the fabric won’t fade or crack even after multiple times in the washer. The method is relatively eco-friendly, especially when compared to plastisol screen printing with its heavy use of toxins or chemicals, but is only used for printing on synthetic t-shirts, i.e. polyester or nylon; in addition, dye sublimation can only be effectively used for white or lightly-coloured T-shirts.

HEAT TRANSFERS

After a design is created and printed on vinyl, a specially-made vinyl cutter is used to shape the design. The unneeded vinyl is then carefully removed, after which a heat press machine is used to print the design onto a shirt. Comfort depends upon the type of cloth it is printed upon, but since each shirt needs its own paper printed individually, it is not as suitable for bulk orders. The appearance is usually glossier in nature compared with shirt designs made from other methods.

PLASTISOL TRANSFERS AND PLASTISOL SCREEN PRINTING

This method is quite similar to screen printing, with the exception that rather than transferring the dye to screens, you transfer it to plastisol and finally to the T-shirt. A cost-effective method, it is also not as messy. The inks themselves are not environmentally friendly. Also, this process does not create transfers which are as durable as those made by other methods.

PUFF PRINTING

Puff screen printing follows the same processes as screen printing, but results in eye-catching, 3D effects being applied to the final design. The 3D or raised look can fully or partially comprise the shirt’s overall design. As with other methods, the ink used is Plastisol-based, but there is also a foaming agent that expands when it reacts to heat, causing the ink to example and thus giving it the recognisable 3D effect.

One of the many advantages of the 3D effect is that it makes a design or logo stand out more than if it had been printed regularly. However, designs made with this method must be simple in nature – puff printing is not suitable for complex images or patterns.

Interested in learning more about t-shirts? Head to the ultimate t-shirt buying guide. See you there.

Prefer plain t-shirt multipacks? we have you covered (literally).